Dispensing

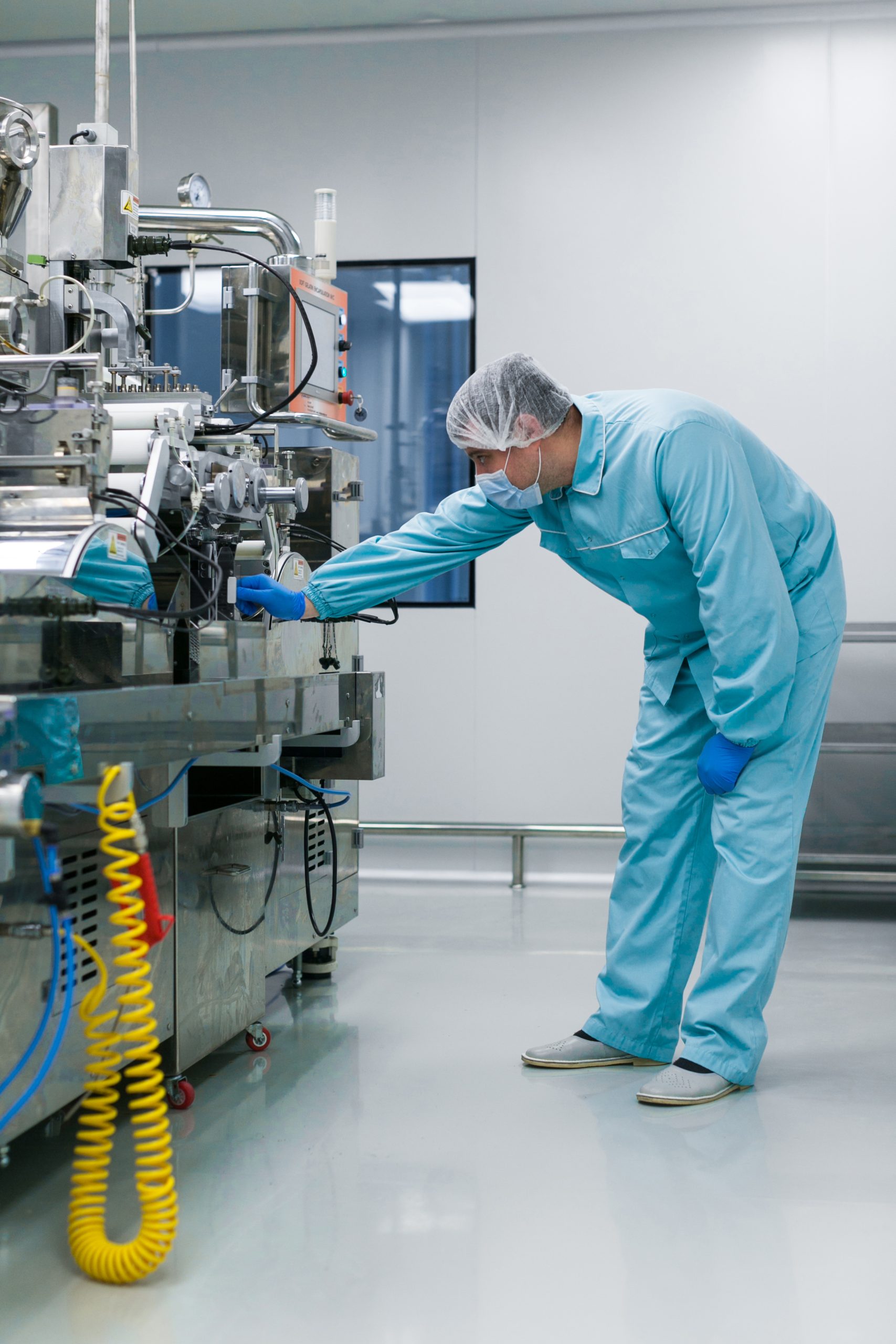

Dosing powders in injection molding or extrusion processes demands specialized expertise. At Optimotion, we’ve seamlessly integrated insights from global powder manufacturers and plastic producers into the development of our Powder Doser Solution. Our advanced system empowers plastic producers with precise dosing, leading to significant cost savings of up to fifty percent on valuable powder additives.

Optimotion’s Powder Doser Solution is a meticulously designed system that revolutionizes the dosing process for powders in injection molding and extrusion applications. The journey begins at the workstation where product dimensions are captured in all three coordinate axes. Using pneumatic components ensures simplified maintenance and energy efficiency, while an industrial-grade platform facilitates precise product weighing.

At the heart of the system is the 180° Pneumatic Rotating System, enabling seamless operations. The fully automatic box/pallet dimensioning system ensures highly precise results. The reliability of the weighing platform is unmatched, providing accurate measurements crucial for the dosing process. Advanced information storage and process traceability technology ensure a comprehensive inspection, setting a new standard in efficiency.

The open architecture of our Powder Doser Solution allows for seamless integration with other systems, providing a holistic approach to industrial processes. Accessory features include a work lamp for enhanced visibility and communication cables for connectivity. Optionally, clients can upgrade their capabilities with a Zebra printer, a Barcode/QR code reader for efficient scanning, and RFID readers for enhanced tracking.

The Powder Doser Solution from Optimotion encapsulates innovation, precision, and efficiency, ensuring a transformative experience in powder dosing for injection molding and extrusion applications.

Measuring and Weighting System

Step into precision and efficiency with our cutting-edge Workstation—a professionally designed powerhouse tailored for capturing maximum product dimensions across all three axes. Engineered with pneumatic components for streamlined maintenance and energy efficiency, this workstation guarantees a thorough inspection, complete with an industrial-grade platform for precise product weighing.

Key Features:

- 180° Pneumatic Rotating System

- Fully automatic, delivering highly precise box/pallet dimensioning

- Highly reliable weighing platform

- Advanced information storage and process traceability technology

- Open architecture for seamless integration with other systems

Accessories:

✓ Illuminate your workspace with the Work Lamp

✓ Stay connected with included Communication Cables

Optional Accessories:

✓ Upgrade your capabilities with the Zebra Printer

✓ Enhance scanning efficiency with the Barcode/QR Code Reader

✓ Boost tracking capabilities with RFID Readers

Unleash the full potential of your operations—where precision meets innovation!

Chemical Volumetric System

At Optimotion, we introduce cutting-edge solutions that redefine precision and efficiency. Our Chemical Volumetric System is a testament to our commitment to excellence in industrial processes. This innovative system seamlessly integrates various sensors and actuators, performing critical functions to elevate your chemical dosing operations.

Key Features:

- Homogenization of Solutions:

- Achieve uniformity in chemical solutions for enhanced effectiveness

- Chemical Dosing Expertise:

- Our system excels in accurately dosing chemicals into the water flow, optimizing the chemical-to-water ratio with unparalleled precision.

How It Works:

The process initiates by supplying pure water to the tank containing the chemical solution, meticulously measured by our state-of-the-art flowmeter. Simultaneously, the chemical is dosed into the system, directly proportional to the flow of pure water. This dynamic relationship ensures optimal performance and resource utilization.

Advanced Sensors and Actuators:

- Flow Sensor:

- Utilizing an ultrasonic flowmeter, our system precisely measures the water flow, ensuring accuracy in every operation.

- Main Pump:

- The main pump circulates the chemical solution with PLC-controlled on/off functionality, providing adaptable speed settings for optimal performance.

- Dosing Pump:

- Our dosing pump, a Walchem EHE series masterpiece, ensures the accurate dosing of pure chemicals into the circulating water, seamlessly integrating technology and functionality.

User Interface:

Our user-friendly interface grants you total control. From monitoring process values to manual operation, alarms, and real-time graphing, our system empowers you to manage operations with ease. Our commitment to transparency is reflected in detailed status indicators and visualizations.

Applications:

- Industrial Processes:

- Ideal for a wide array of industrial applications requiring precise chemical dosing.

- Water Treatment:

- Ensures accurate chemical dosing for water treatment plants, promoting efficiency and reliability.

Why Choose Optimotion:

- Precision in Every Drop:

- Our system guarantees precision in chemical dosing, optimizing your operational efficiency.

- User-Centric Design:

- The user interface is intuitive, providing easy control and monitoring for operators.

- Reliability Redefined:

- Backed by advanced sensors and actuators, our system ensures reliable and consistent performance.

Transform your chemical dosing operations with Optimotion’s Chemical Volumetric System. Embrace innovation, optimize efficiency, and redefine excellence in your industrial processes.

Contact us today to explore how our Chemical Volumetric System can revolutionize your operations.